Not only in terms of performance but also under the fire of environmentalist rules, car manufacturers are starting to introduce more and more hybrid or even pure electric cars. Tesla, led by former PayPal CEO Elon Musk, was the driving force behind 100% electric cars. When adapting this option comes a big problem, the duration, and durability of the batteries. About a year ago, a battery researcher at Dalhousie University, Canada, and pioneer in the development of the lithium-ion battery, Jeff Dahn, created a new partnership with Tesla, which consisted of increasing battery life.

Tesla in front of investigation

The research was above expectations, achieving the expected results 4 years before the end of the investigation. The research team was able to double the useful battery life of Tesla’s product batteries. Dahn achieved such improvements by designing equipment that accurately monitors the batteries during loading and unloading to identify the causes of degradation. Dahn does not claim full knowledge about the chemical process of the degradation, but the equipment he developed allowed them to test new protection chemicals more accurately and much more quickly, resulting in a significant discovery on cell longevity. With these new test methods, it was possible to discover that a certain aluminum coating was superior to any other material. Cells tested with this coating showed practically no degradation under a high number of cycles at moderate temperature and only little degradation under extreme conditions. One of his students joining the project went on to work for the battery cell research group internally at Tesla. Another started a company to market the battery cell test machines they developed. Its customer list includes Tesla, but also Apple, GM, 24M and many other major battery manufacturers. Dahn said, “in the description of the project we sent to the CRSNG (Natural Sciences and Engineering Research Council of Canada) to get government funding for it, I wrote that the goal of the project was to double the life of the cells used in Tesla products at the same voltage Uppercut. We exceeded this in Round 1. So that was the goal of the project and has already been overcome. We will not stop, we have four more years to investigate. Let’s go as far as we can”.

Technology for residential storage batteries

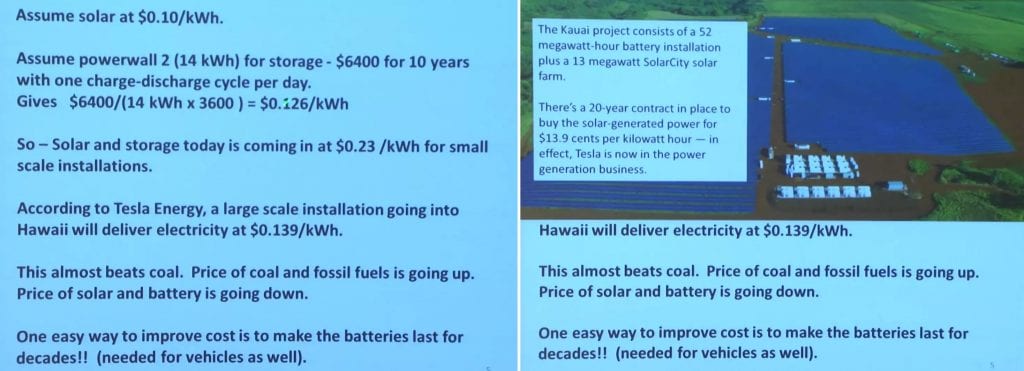

While Dahn’s research focused on the Nickel- Manganese -Cobalt Oxide (LiNiMnCo-NMC) cells, which Tesla uses for its Powerwall and Powerpack storage products and their vehicles, Dahn said they are also working In this format. It is possible that the launch of the new Model 3 batteries planned for June this year, in Gigafactory 1, already has the technology discovered by the Dahn team. Dahn explained that by increasing the life of these batteries, Tesla reduces the cost of kWh it considers in the accounts of its residential projects and large-scale projects. An example of this is the cost of $ 0.23per kWh for solar storage and $ 0.139per kWh for the large scale, based on current Tesla projects:-

The researcher added that since Tesla uses aluminum in the manufacture of the chassis in its products, there is no reason why both cars and batteries can not last for 20 years. So, what do you think about this? Simply share your views and thoughts in the comment section below.